Quality Management

Texture Maker's quality control laboratory is the cornerstone of the company's commitment to product excellence and safety. It plays a crucial role in the quality management system, aiming to meet international standards such as ISO 22000, FSSC 22000, and HACCP. The laboratory is also striving to obtain TAF association certification for ISO 17025, underscoring its exceptional capabilities in food safety and quality.

The main goal of the quality control laboratory is to ensure the safety, quality, and compliance of all products. Through continuous quality monitoring and improvement, the team identifies and resolves potential quality issues, maintaining the products' excellent reputation in the market. By adhering to international standards and implementing continuous quality management practices, Texture Maker's quality control laboratory ensures that the company's products maintain a leading position in the market and provide customers with reliable food ingredients.

Factory Management

Workplace Safety

[Food safety is paramount in food processing; workplace safety is the cornerstone of factories]

With employee safety as the top priority, Texture Maker has established occupational safety and health management personnel in accordance with regulations and implemented strict workplace safety policies. All employees receive professional training to ensure compliance with safety standards, creating a work environment with zero accidents and continuous safety training results.

Standardization

The company firmly believes that standardization is the key to ensuring product quality and production efficiency. We adhere to international industry standards and continuously improve and update production processes to ensure product consistency, thereby gaining customer trust.

Digitization

Technology-driven production

In the rapidly evolving era of intelligence, we have integrated digitization into our core strategy. By leveraging the Internet of Things (IoT) and Industrial Internet of Things (IIoT) to collect and analyze data, and by cooperating with automated production lines, we significantly improve production efficiency and quality control. This results in better products and services.

Low Carbon Footprint

Environmental protection is our commitment. We achieve ESG sustainable development goals through energy conservation and emission reduction and green supply chains. Additionally, we are dedicated to a university-industry cooperation project focused on developing a factory-wide low-voltage AC power monitoring smart IoT system. This system reduces raw material waste, improves the energy efficiency of machinery and equipment, and pursues carbon footprint reduction and sustainable development through various carbon reduction strategies.

Automation: Doubling Per Capita Output with Robotic Arms

Mechanized processes are born out of the recognition of the pain points and needs of traditional industries. Investment in automation has yielded remarkable results, doubling per capita output, and significantly alleviated the pressure of labor shortages.

Food Sanitation and Safety

Establishing a food safety early warning mechanism

Food safety workshops and trainings are conducted every year for all employees to implement food safety awareness and share the responsibility of food safety with the whole factory.

Strengthening the food safety system of the supply chain

We strive to constantly reinforce the on-site inspection mechanism and improve food safety risk communication with suppliers to ensure effective source management of the food safety system.

Building a food safety culture

We monitor international food safety information and regulations and trends every month, and share them with relevant departments to propose corresponding countermeasures, and comply with food safety laws and regulations.

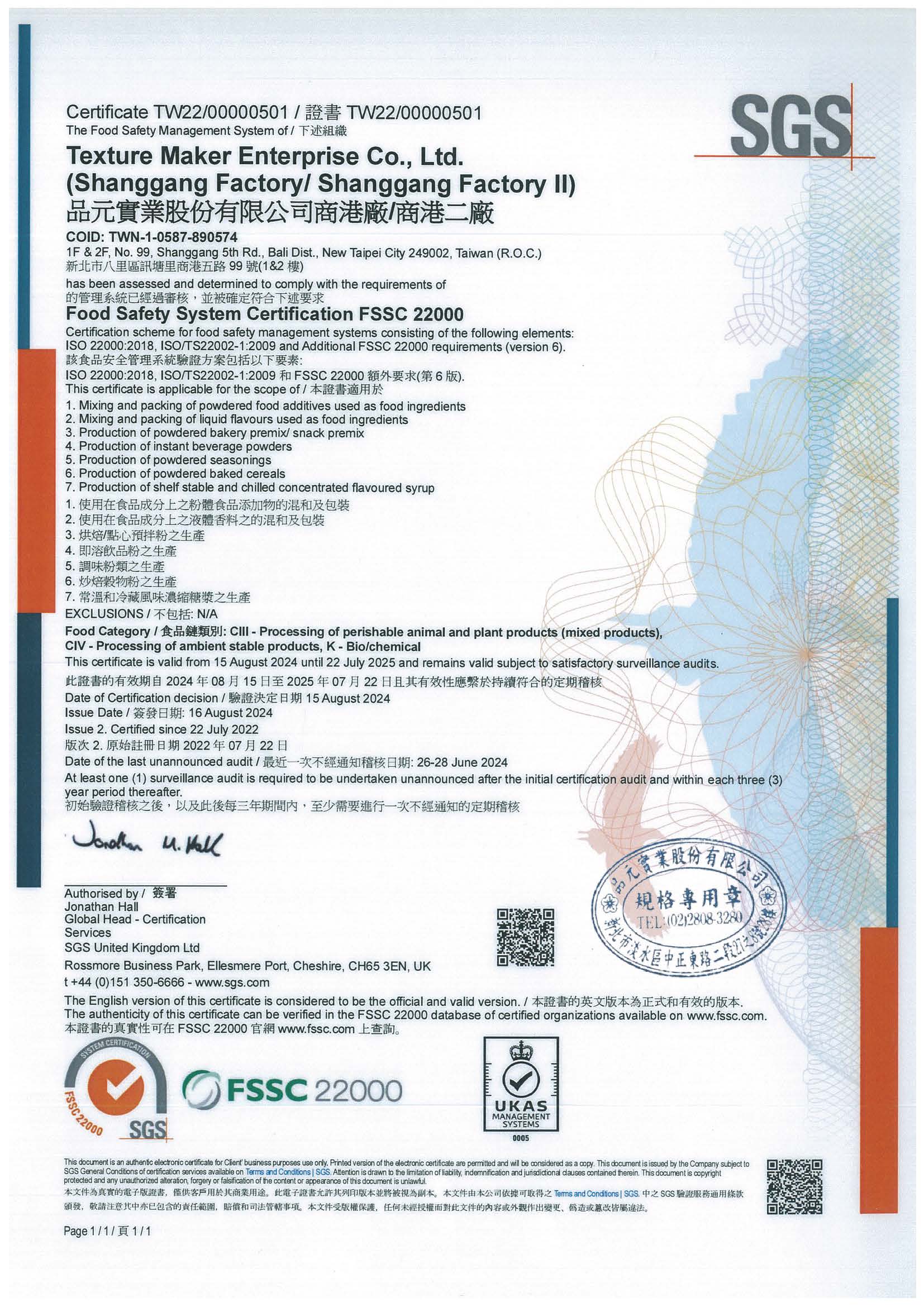

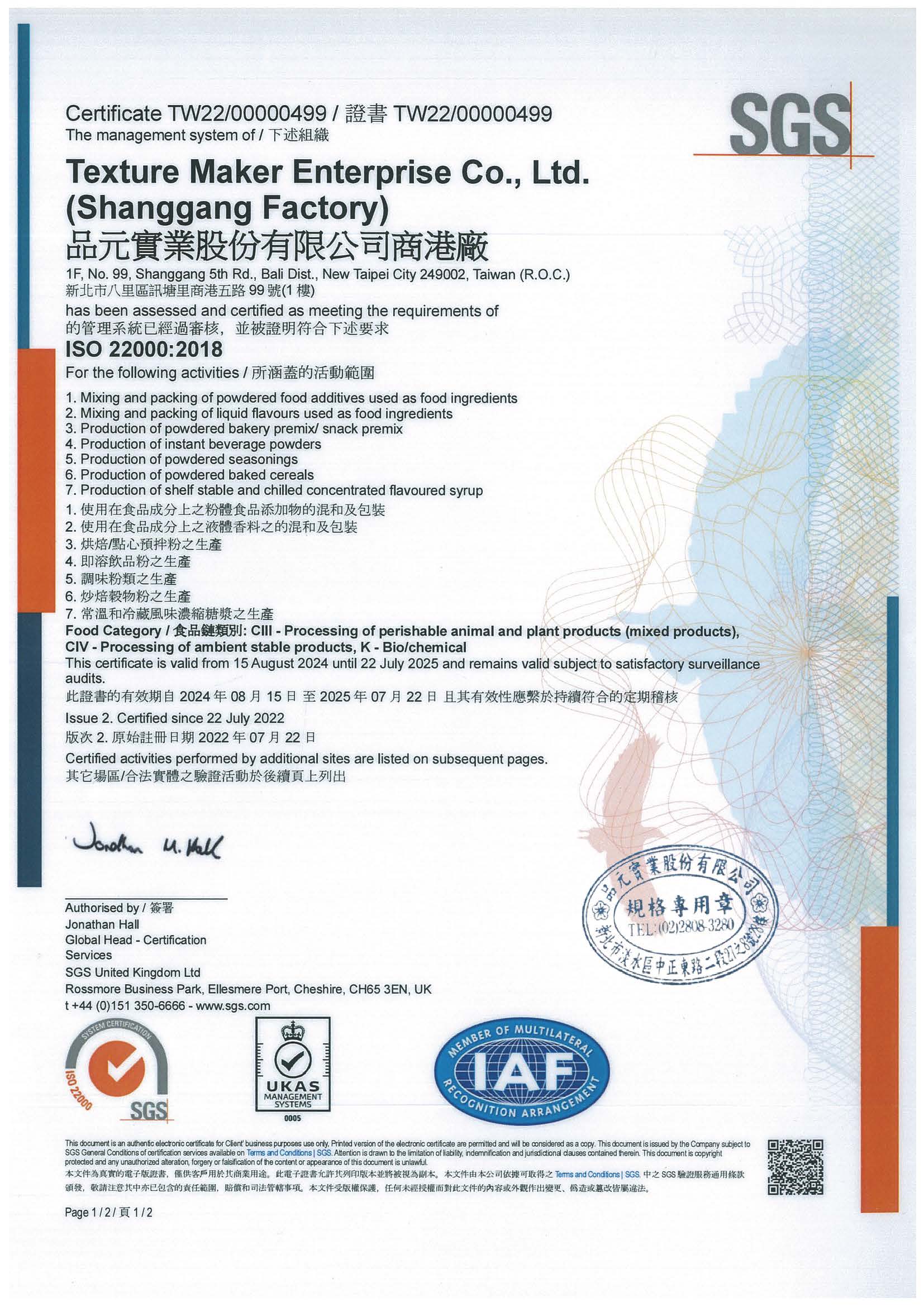

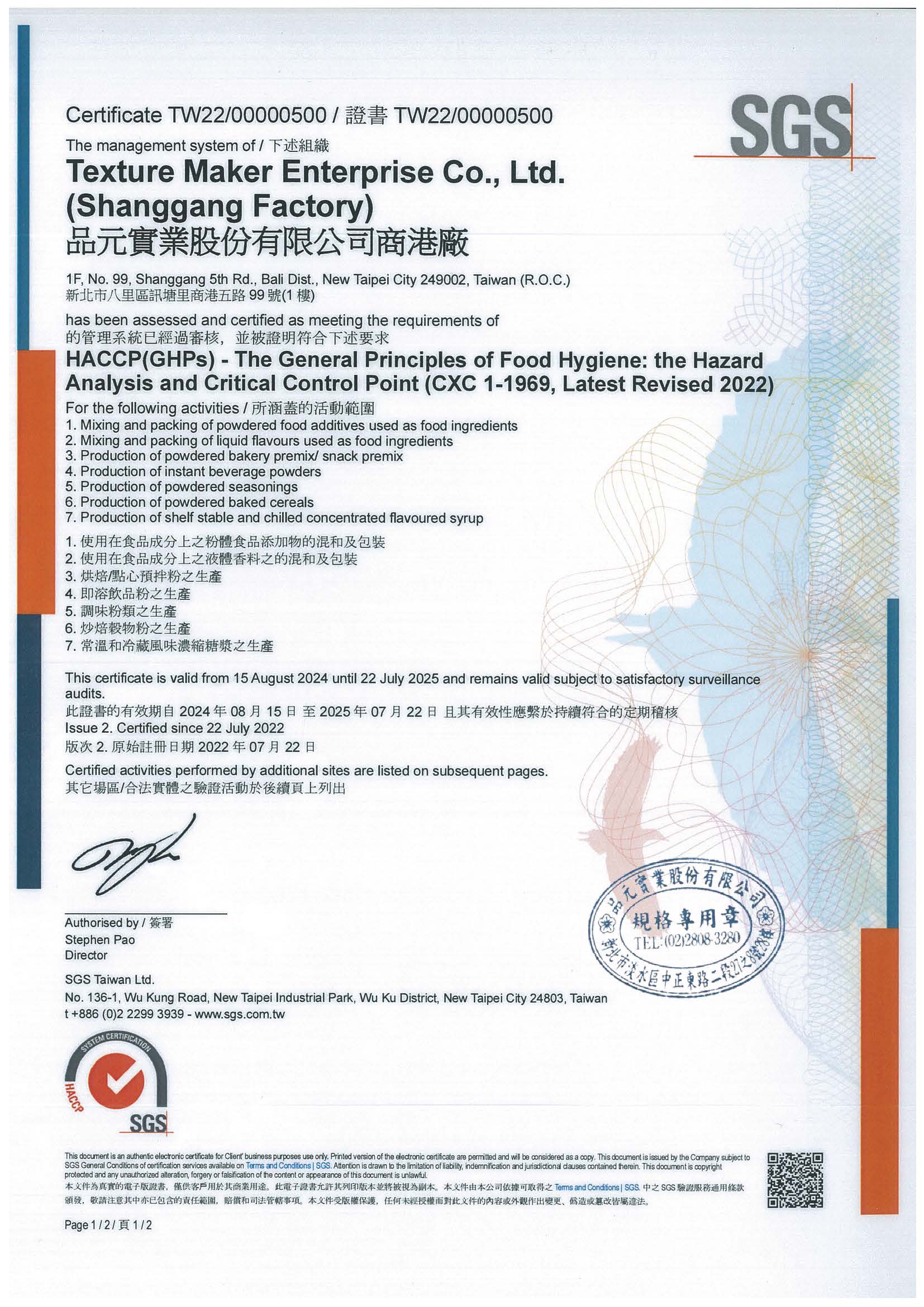

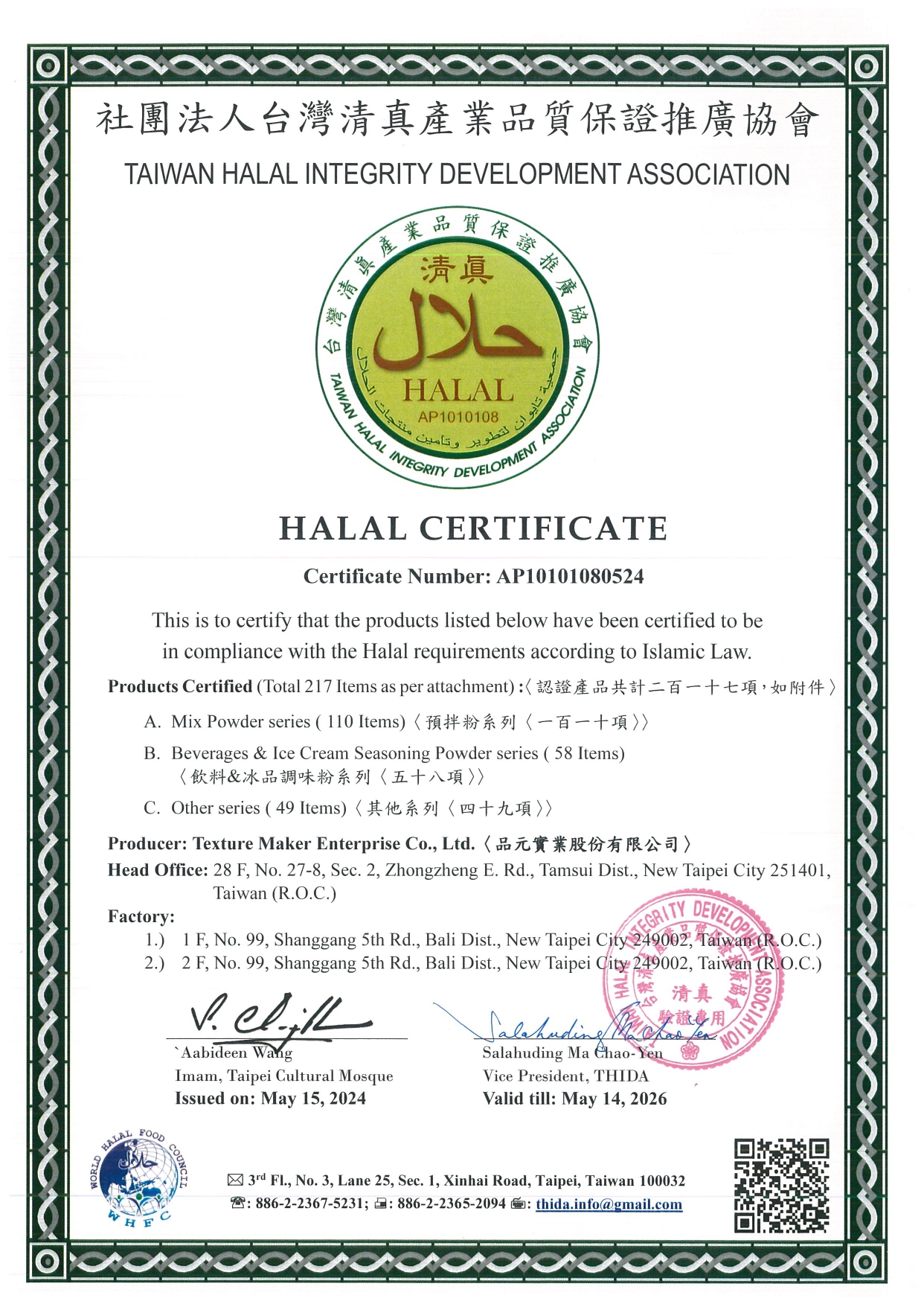

Accreditation

FSSC 22000

ISO 22000

HACCP

ISO 17025

Halal Certificate

D&B D-U-N-S Certified